The issue of lightweight construction evolved into a strategic project at Audi in 1982. The objective was to reinvent the self-supporting body – with a new material and a geometry that was specifically customised to suit it.

The development work was undertaken as an integrated project, which yielded 40 patents and patent applications and broad-based know-how. At the 1985 Hanover Fair, the brand presented the body of an Audi 100 made of aluminium, still with a traditional monocoque design. And the concept sports cars of 1991, the Audi Avus quattro and the Audi quattro Spyder, still had shells made of the light metal, but there were supporting frames underneath.

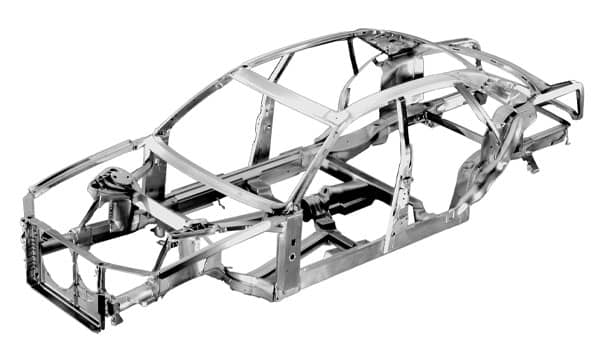

The new technology was ready to go into production by 1993 though: The International Motor Show in Frankfurt/Main featured a gleaming silver showcar with an unpainted body made of polished aluminium. The predecessor of the A8 was called the ASF, short for Audi Space Frame. The production model which followed the year after was the world's first mass-production vehicle to have a self-supporting aluminium body. The body of the A8 weighed just 249 kilograms, and it already featured the design which it still has today. Its 336 individual components were dominated by the sheet metal parts, ahead of the profiled and cast components. Roughly 75 per cent of the assembly work was done by hand.